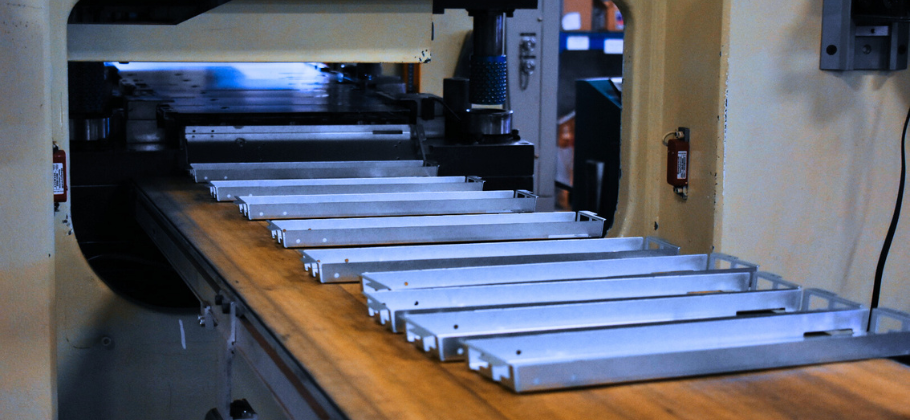

Progressive stamping for medium to high volume manufacturing.

By working with an experienced, vertically integrated components partner with in-house progressive stamping capabilities, like MPE Inc., we can ensure your components are produced with the highest quality standards while reducing costs and increasing the product’s time.

Our in-house stamping capacity includes multiple progressive stamping machines, with a tonnage range from 110-200 ton and a bed size up to 40” x 84”. All our machines are specifically designed to manufacture products that require high aesthetics.

Materials we can work with, ranging from 0.015”-0.250” thickness:

- Steel

- Aluminum

- Galvanized steel

- Galvannealed steel

- Aluminized steel

- Stainless steel

- Copper

- And more!

Resolve pain points with end-to-end expertise.

With over 20 years of experience working with sensitive and highly aesthetic materials, your products will be in the right hands through customized measures such as:

- Rubberized rollers

- Rapid air straighteners for light gauge and sensitive straightening

- Pre-painted material runs with vinyl masking

- No marking of materials

Other benefits of progressive stamping:

- Greater control on inventory and flexibility in revising vs. casting

- Consistency and accuracy

- Complex forms

- Critical to quality specifications

- Tight tolerancing